Dive Brief:

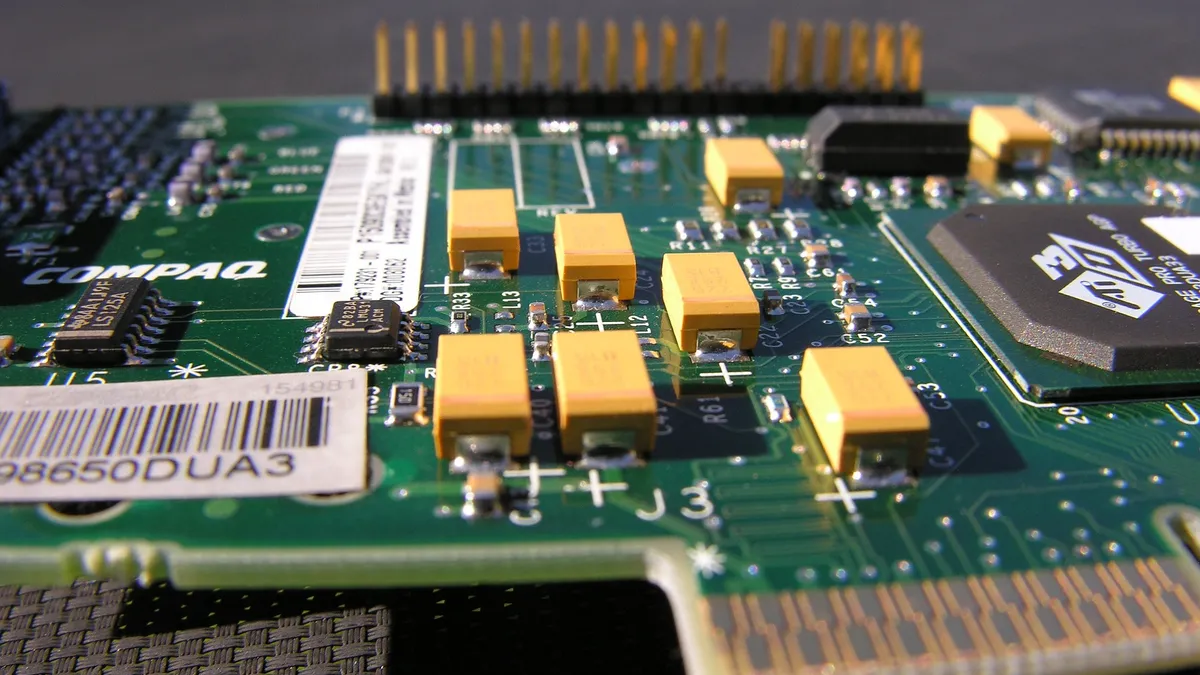

- Nearly 70% of U.S. electronics manufacturers reported lower profit margins as a result of the U.S.-China trade war and tariffs on products they import, according to a study by IPC, an association representing the electronics manufacturing industry. IPC surveyed its U.S. members between Sept. 25 and Oct. 2.

- "Lower profitability due to increased tariff costs appears to be hindering investment in the U.S.," the study said. Twenty-one percent of companies said they are reducing investment in the U.S., and 13% said they're laying off workers or cutting back on hiring.

- More than half of the companies said they are sourcing products from countries other than China as a direct result of tariffs.

Dive Insight:

The electronics industry faces a similar pricing conundrum to several other sectors. Tariffs have created higher costs on imported goods, but the answer is not always as simple as raising prices for downstream customers.

IPC said 55% of companies reported higher prices as a result of tariffs. On the fourth list of U.S tariffs on China, valued at $300 billion, more than half the products are technology imports, according to the Consumer Technology Association (CTA). While 58% of firms told IPC they raised prices to cover the costs, one-third of respondents said they couldn't raise prices.

"It is common for companies in the industry to have long term contracts with guaranteed prices. This makes it essentially impossible for companies to change pricing, at least in the short-run," IPC said. Another reported factor in keeping prices steady was the need to remain competitive, especially with firms not impacted by U.S. and China tariffs.

Lower margins and higher costs aren't derived from tariff-related price hikes alone though. The act of navigating the trade war, which IPC referred to as "administrative and operational burdens," has also taken a toll on company balance sheets.

IPC named burdens such as identifying which suppliers added tariffs and which products face duties, "keeping track of changing rules" and reallocating tariff costs. Other industries have noted cost increases in warehousing and storage resulting from the pull-forward of inventory to circumvent tariffs.

In figuring out the supplier piece of the puzzle, one manufacturer reported increased work and confusion because each vendor accounts for tariffs differently. "One vendor charges a flat percentage rate, another just increases their cost, another gives an arbitrary number — we have no way of knowing if they are charging more than the 25%," the OEM said in the survey.

Individual business concerns have impacted overall industry sentiment, with one in five firms in IPC's study reporting reduced investment in the U.S. — the exact opposite of the stated intent of the U.S.-China trade war